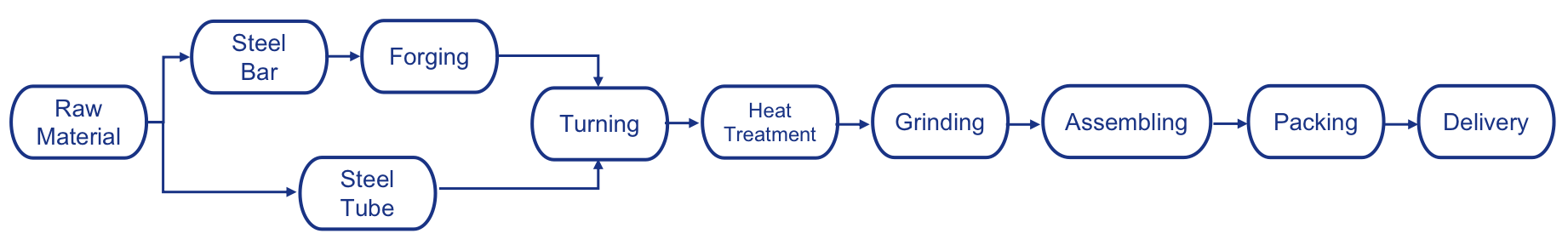

We choose the best materials and employ stringent standards on the control of Oxygen, Titanium, Sulphur, Phosphorus. In particular, the oxygen content is strictly controlled below 10ppm, which improves the purity of steel effectively, and thus improves the bearing life.

According to the bearing size scope and different performance requirements, we select turning rings or forged rings.

We are equipped with 5 rolled-rings production lines to strictly control the initial forging and final forging temperatures.

The compactness of the ring is significantly improved by forging.

We have three advanced Aichelin heat treatment lines, using protective atmosphere salt-bath heat treatment process. The outstanding heat-treatment stability improves the material rigidity, makes the geometry more compact and better dimensional stability, so as to ensure the high-load performance of the bearings.

For each batch of products, we conduct online heat treatment performance inspection to check the hardness and metallography of the materials.

The heat treatment line can also be customized according to different requirements.

We have more than 80 automatic grinding lines. After years of continuous research and design, the automatic grinding lines have been developed to the third generation.

The automatic lines can deal with large quantities of products. It carries out automatic grinding process, whilst implements online inspection of all dimensions. This significantly improves the product quality consistency and production efficiency.

We have 33 automatic assembly lines. Every line integrates parts feeding, demagnetization, cleaning, rings and balls matching, cage installation, grease filling, shield pressing, anti-rusting and laser marking.

Meanwhile the automatic assembling lines are equipped with online automatic measurement of rings’ dimensions, rolling elements sorting, vibration measurement and clearance measurement. Every step is fitted with error prevention device. The whole automatic processes ensure the consistency of the quality.