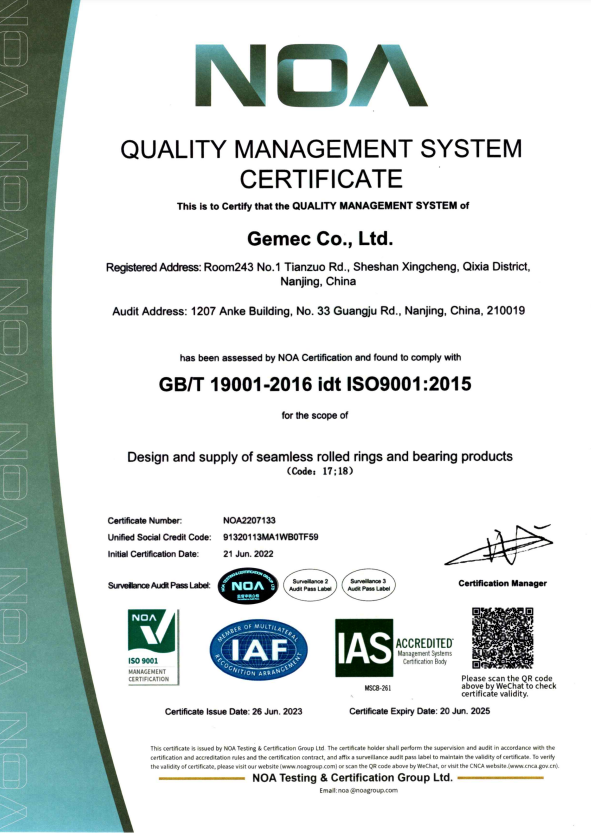

We select high quality steels from proven reputable steel mills.

Setting up high standard requirements to ensure the high quality from very beginning.

100% material IQC implemented based on individual heat No. from steel mill.

Continuous casting, forging bar, blooms casting used for different size of rings.

Cutting weights are precisely calculated to reduce the cost at the beginning.

Pouring riser of blooms casting strictly removed to ensure the purity of the material.

Skillful operator to ensure the efficient charging.

Natural gas and electricity furnaces with well equipped temperature control system to ensure the heating efficiency.

One rotate furnace coupled with automatic production line.

Continuous casting, forging bar, blooms casting used for different size of rings.

Cutting weights are precisely calculated to reduce the cost at the beginning.

Pouring riser of blooms casting strictly removed to ensure the purity of the material.

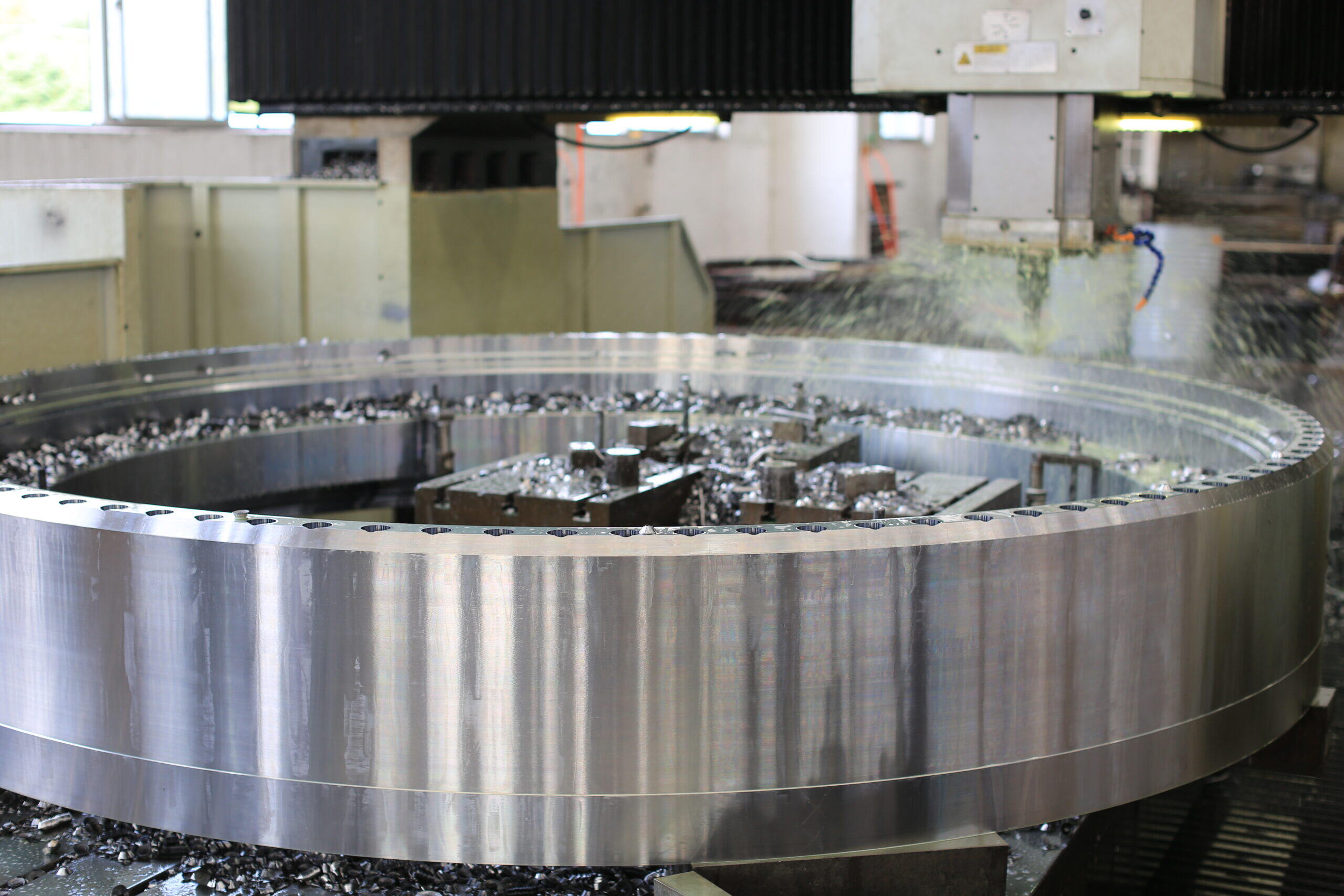

Multiple rolling lines can roll up to 1m, 2.5m, 6m, 8m, 9m diameter rings.

Max. 800tonne rolling power can be reached.

One 8m automatic production line can roll up to 50tonne rings.

Multiple furnaces powered by natural gas and electricity can handle annealing, normalizing, quenching, and tempering.

Max. 9m diameter rings can be treated.

Before NDT, rough machining will remove the black layer and build a suitable roughness of the surface.

Max. 9m diameter rings can be machined.

To detect the surface and internal defect, the following NDT implemented by certified operators.

Dye Penetration Inspection

Ultrasonic Testing

Magnetic Particle Inspection

Surface Hardness Testing to verify the quality of Heat-treatment.

Cutting partial ring from the ring body to make corresponding samples for following physical & chemical tests according to customers’ requirements and standards.

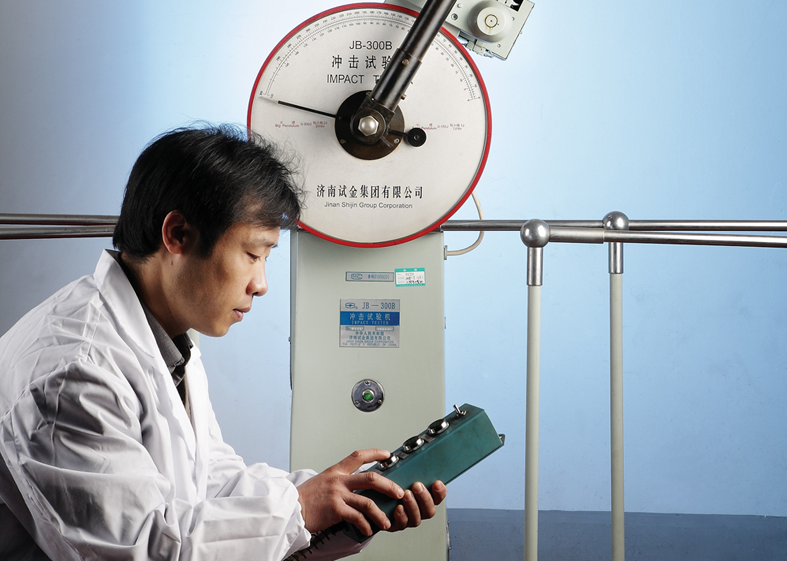

Destructive testing according to customers’ requirements and standards as below:

Metallography test

Mechanical Properties test

Notch Impact Energy test

Raceway, bore holes, side holes, filling plug, gears and so on can be full filled according to customers’ requirements.

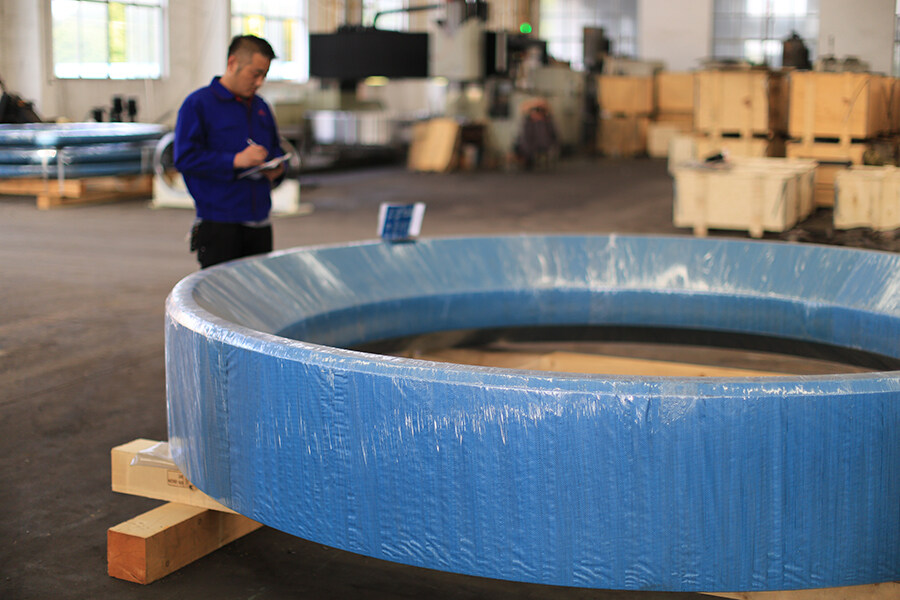

100% dimension inspection implemented before packaging.

3rd party inspectors will check the process randomly.

Antirust process according to customers’ requirements before packaging.

Rings will be packed in different style based on different delivery condition to be suitable for loading and delivery and reduce the impact on environment.

Transport subcontract to our partners or carriers of customers’ choice.